Alcoa Australia

Elysha Maxwell

6.30 AM

I wake up and get dressed. Because I work at a refinery, this means putting on my high-vis. While the combination of yellow and blue leaves me looking somewhat like a cross between a minion and a Lego person, I am eternally grateful for how comfy my daily work clothes are, and for the time I save from not having to pick out clothes in the morning.

Once I’ve got myself ready and my bag packed, I drive to work. Fortunately, I work at Alcoa’s Kwinana refinery, which is only a short 15-20 minute drive from my house.

7.30 AM

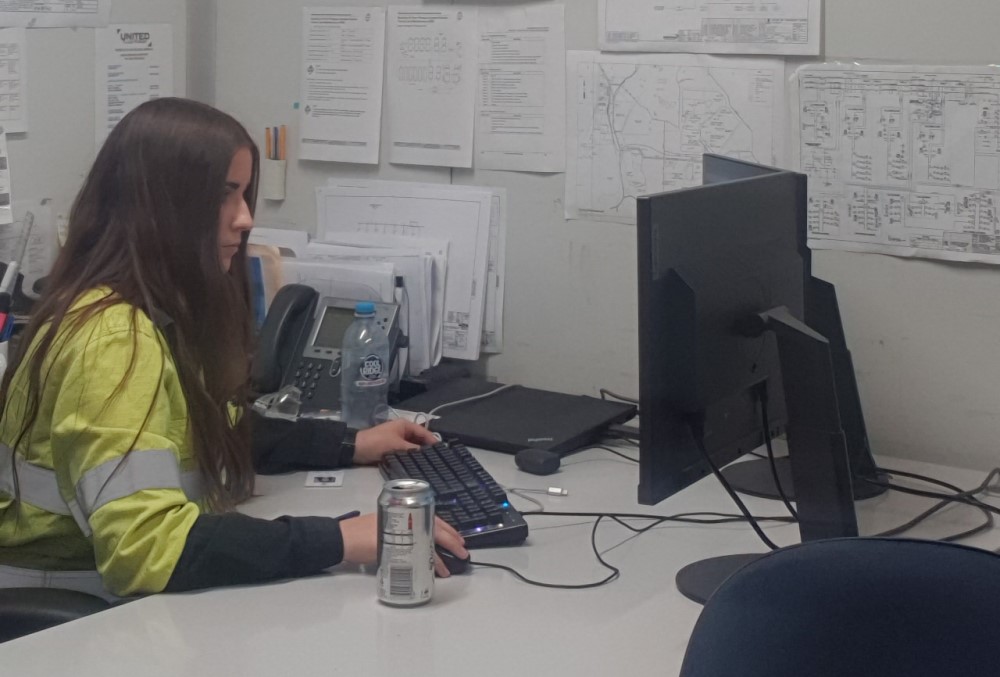

I usually start my day by reading through my emails. While there aren’t anything too pressing first thing in the morning, I read through anything I might have missed and respond to anything I didn’t have time to respond to the day before.

I also use this time to look over my objectives and priorities spreadsheet. This is a spreadsheet that I use to track all the tasks that I am responsible for, and what stage of completion I have currently progressed these tasks to.

8.00 AM

A lot of the work that I do involves coordinating with other people on-site. For example, if I need to do some tests on a piece of equipment that requires it to be offline or in an altered state for a period of time, I would need to coordinate with the operators from the op-centre that uses that piece of equipment, in order to arrange an appropriate time to conduct the tests.

To gain access to electrical cabinets and panels, I rely on the site’s Electrical and Instrumentation (E/I) department who also assist me in performing certain tests on equipment and determining/verifying electrical equipment details. I often need to liaise with the site’s E/I supervisor to arrange convenient times to meet with the electrician that day.

I find that this time of the morning is good to communicate my plans for the day and lock in times with operators and electricians before their days fill up with other plans.

8.30 AM

Now it's time to get to work. The morning is usually the most chaotic time of the day. I use it to progress my short-term priorities and if a job has come up in the plan that requires electrician engineering assistance, it will be brought to my attention around this time.

Today my first job is to prepare a number of risk assessments. The op-centre I work in, OC3 Precipitation, manages a large amount of equipment. This means that some days there is simply not enough time in the day to complete all the work that needs to be done and some jobs need to be scheduled for a later date. Prioritising what work needs to be done first becomes essential for the op-centre. Risk assessments are a tool that we use at Alcoa to quantify the risk that a certain system or piece of equipment currently poses. Once a risk assessment is completed, people who view it can easily see exactly why the work needs to go ahead and how important the work is in comparison to other jobs that need to be completed.

Next, I work on a mark-up of a drawing. It is important that the electrical and mechanical drawings in our system stay updated so that we have an accurate depiction of the equipment on our refinery. Earlier this week, I had a job that involved replacing a protection relay, and I made quick mark-ups on a paper copy to show the necessary updates that needed to be made. Today I am updating the drawing properly on the electronic copy and sending it through to our drafting team.

While I am working on the mark-up, I get an email response from one of our vendors returning a quote for a circuit breaker. I need this information for one of the scopes of work that I am working on, so I update the scope with the information I have received.

Lastly, I begin organising the April graduate day. Alcoa graduate days are held monthly and involve a wide range of technical and soft skills training, informative presentations, and social activities. The program is largely run by the graduates – for the graduates. The day I have put my name down to organise involves a tour of one of our refinery powerhouses, technical presentations that capture the internal workings of the powerhouse, a basic introduction into instrumentation and control and an afternoon team building activity.

10.00 AM

Time to leave the comfort of my cushy air-conditioned office and head to the outside world.

Kidding aside, I love the fact that working on the refinery puts me in such close proximity to the equipment that I am responsible for installing, maintaining and improving. Having exposure to the internal workings of equipment that I get during shutdowns and breakdowns helps me understand how they work much better than any manual could.

First, I check on the data loggers that I set up in one of our Motor Control Center (MCC) rooms a few days earlier. This is to ensure that they are still working and to download the data they have captured for further analysis. Next it’s time to head up the elevator to the top of our precipitation tanks. On top of one of the tanks is a radar instrument that indicates the fill level of the tank. When these instruments act up we verify that there are no physical faults with them and ensure that they are still calibrated correctly.

The top of the precipitation building is hot and steamy, so it is not always an enjoyable place to be standing- but the views of the refinery are definitely the best from up there.

11.00 AM

Every week the Kwinana electrical department gather for their weekly meeting, run by our senior electrical engineer. This meeting is used to review the week just past and to take a glimpse into the week to come.

The topics discussed include any new jobs that have come up, any struggles or roadblocks that people have come across, big or important jobs that are coming up in the plan and the overall performance status of the refinery.

As a graduate, I find these meetings invaluable. Not only because they give me an opportunity to regularly reach out to experienced engineers with any questions that I have, but also because overhearing the response to the struggles and technical queries of my colleagues means that when I come across these struggles and queries in the future, I now have some knowledge to help me solve them. The meeting also helps us all stay in the loop with what work is coming up in the near future and what jobs the rest of the team are currently working on.

12.00 PM

The best time of the day. The electrical department eats lunch together in our building’s conference room.

Today we are having a farewell lunch for one of the graduates. He has finished his Kwinana rotation and will begin work in Pinjarra next week. (As part of the Alcoa graduate program graduates get to rotate throughout the three refineries; Kwinana, Pinjarra and Wagerup.)

1.00 PM

After having some time to eat, relax and gather my plans for the afternoon, I head back out into the refinery to meet with one of our site electricians.

There are two items on the agenda for this meetup. Firstly, I need access to a decommissioned starter panel in one of our MCC rooms. I am intending to upgrade this panel and need to confirm that the internal wiring matches that of the drawing I have available for the starter panel. This is so that there are no nasty surprises when the upgrade goes ahead. Secondly, I need the assistance of the electrician to verify the closest purge water line to the spot on the top of our tray rakes where I intend to install a pressure transmitter.

2.00 PM

Back to the cushy office.

I use the afternoon to tackle my more long-term priorities. These are the tasks on which progress is made, but which may take several weeks or even months to complete.

Today I am looking at one of our Engineering Management Strategies. These strategies are used by Alcoa to ensure that the assets in a system are being maintained correctly and maintained regularly.

This strategy has already largely been developed by other engineers in my op-centre but I need to sort through the relevant instrumentation parts of the strategy to ensure all instruments are captured and that the right maintenance is being performed on them.

3.00 PM

While my work can span across the refinery, my primary role is to maintain the electrical equipment in OC3.

Due to the large amount of equipment in this op-center the priorities can be quite fluid- especially if there are any unexpected breakdowns or failures of equipment in the area.

Every week I meet with the OC3 Senior Reliability to realign my electrical priorities with that of the op-center. This is another meeting that is incredibly valuable to me as it allows me to clarify new jobs face to face and allows me to easily communicate any roadblocks I’ve faced regarding the priorities from the week before.

3.30 PM

While my workday technically finishes at 3.30 pm, I like to stay back for an hour or so to tidy up any loose ends from things I was working on during the day and to update my objectives and priorities spreadsheet.

5.00 PM

Time to head home. I usually spend what is left of my afternoon doing a few household chores and watching Netflix on the couch.

6.30 PM

I play for a local women’s soccer team that trains twice a week. I find it a much more entertaining way of getting my weekly exercise as compared to going to the gym.

8.30 PM

When I get home from training, I’m pretty tired from the day. I make my dinner, shower and watch some more Netflix to unwind and get ready for bed. One thing full-time work has taught me is you can’t undervalue a good night’s rest. I always try to make sure I’m in bed by 10.00 pm so I get my full 8 hours.